Roof curbs are essential components in roofing systems, providing support, stability, and functionality. They serve as platforms for mounting rooftop equipment such as HVAC units, exhaust fans, skylights, and more. Understanding the various types of roof curbs available is crucial for architects, contractors, and building owners to ensure optimal performance and longevity of their roofing installations. In this comprehensive guide, we delve into the different types of roof curbs and their respective applications.

Standard Roof Curbs:

Standard roof curbs are the most common type, typically made from galvanized steel, aluminum, or other durable materials. They come in various sizes and configurations to accommodate different equipment and roofing systems. Standard GRP Roofing provide a stable base for mounting equipment and ensure proper drainage on flat or low-slope roofs.

Pitched Roof Curbs:

Unlike standard roof curbs designed for flat or low-slope roofs, pitched roof curbs are specifically crafted for sloped roofs. These curbs are angled to match the pitch of the roof, ensuring a secure and proper fit for equipment installation. Pitched roof curbs are crucial for maintaining the integrity of the roofing system while accommodating equipment placement on inclined surfaces.

Wooden Roof Curbs:

Wooden roof curbs offer an alternative to metal curbs, providing a lightweight and cost-effective solution for certain applications. They are commonly used in residential and light commercial settings where the load requirements are minimal. Wooden roof curbs are relatively easy to install and can be customized on-site to meet specific project needs.

Prefabricated Roof Curbs:

Prefabricated roof curbs are factory-made to precise specifications, ensuring consistency and quality in every unit. These curbs are often constructed from welded steel or aluminum and come in standard sizes or can be custom-built to fit unique requirements. Prefabricated roof curbs streamline the installation process, saving time and labor costs on-site.

Adaptable Roof Curbs:

Adaptable roof curbs are designed to accommodate various types of equipment and roofing configurations. They feature adjustable components such as height, width, and slope to adapt to different installation scenarios. Adaptable roof curbs offer versatility and flexibility, making them suitable for retrofitting existing buildings or accommodating future equipment upgrades.

Specialty Roof Curbs:

Specialty roof curbs cater to specific applications or challenges in roofing systems. This category includes curbs designed for unusually shaped equipment, such as dome skylights or custom ventilation units. Specialty roof curbs may also incorporate features like vibration isolation or sound attenuation to enhance performance in specialized environments.

Safety Roof Curbs:

Safety roof curbs prioritize structural integrity and fall protection, especially in rooftop areas accessed by maintenance personnel. These curbs are engineered to withstand higher loads and may include built-in guardrails or tie-off points for workers’ safety. Safety roof curbs are essential for compliance with occupational health and safety regulations.

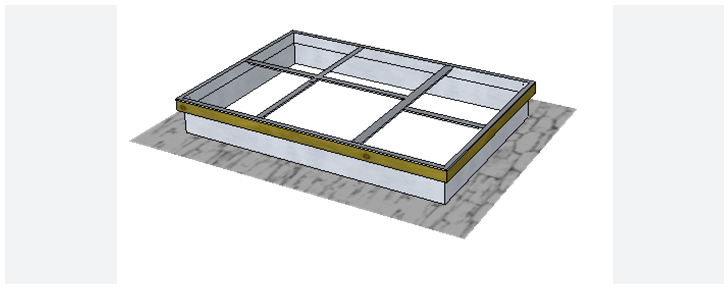

Insulated Roof Curbs:

Insulated roof curbs are designed to minimize thermal bridging and energy loss in roofing systems. These curbs feature insulation layers, such as foam or rigid board, sandwiched between exterior panels to provide thermal resistance. Insulated roof curbs help maintain consistent indoor temperatures and reduce heating and cooling costs, making them ideal for energy-efficient building designs.

Customizable Roof Curbs:

Customizable roof curbs offer tailored solutions for projects with specific requirements or architectural constraints. These curbs are fabricated according to precise specifications, taking into account factors such as equipment dimensions, roof slope, and building codes. Customizable roof curbs enable architects and contractors to achieve seamless integration with the overall building design while meeting functional needs.

Curbs with Integrated Drainage Systems:

Curbs with integrated drainage systems are designed to manage water runoff effectively on flat or low-slope roofs. These curbs feature built-in channels or scuppers that direct water away from equipment and prevent pooling on the roof surface. Integrated drainage systems help mitigate the risk of water damage and prolong the lifespan of roofing materials, particularly in regions prone to heavy rainfall or snow accumulation.

Fire-Rated Roof Curbs:

Fire-rated roof curbs are engineered to meet stringent fire safety standards and regulations. These curbs are constructed from fire-resistant materials and undergo testing to ensure compliance with building codes and insurance requirements. Fire-rated roof curbs provide an additional layer of protection against the spread of flames and smoke, enhancing occupant safety in commercial and industrial buildings.

Low-Profile Roof Curbs:

Low-profile roof curbs are designed for installations where space constraints or aesthetic considerations are a concern. These curbs have a reduced height profile compared to standard curbs, allowing for discreet placement of equipment without protruding significantly above the roofline. Low-profile roof curbs blend seamlessly into the architectural design while still providing robust support for rooftop units.

Roof Curbs with Seismic Restraints:

Roof curbs with seismic restraints are engineered to withstand the forces exerted during earthquakes or other seismic events. These curbs incorporate specialized hardware, such as seismic clips or straps, to secure rooftop equipment and prevent displacement or damage. Roof curbs with seismic restraints are essential for ensuring structural stability and minimizing the risk of equipment failure in seismic-prone regions.

Environmentally-Friendly Roof Curbs:

Environmentally-friendly roof curbs prioritize sustainability and eco-conscious design principles. These curbs may be fabricated from recycled materials, feature low-VOC coatings, or incorporate green roofing technologies such as vegetative roofs or solar panels. Environmentally-friendly roof curbs contribute to reducing the carbon footprint of buildings and promoting environmental stewardship in construction practices.

In conclusion, the selection of roof curbs plays a critical role in the functionality, efficiency, and safety of roofing systems. By understanding the different types of roof curbs available, stakeholders can make informed decisions based on project requirements, budget constraints, and performance expectations. Whether it’s a standard curb for a commercial HVAC unit or a specialized curb for a unique rooftop feature, choosing the right curb ensures the long-term success of roofing installations.